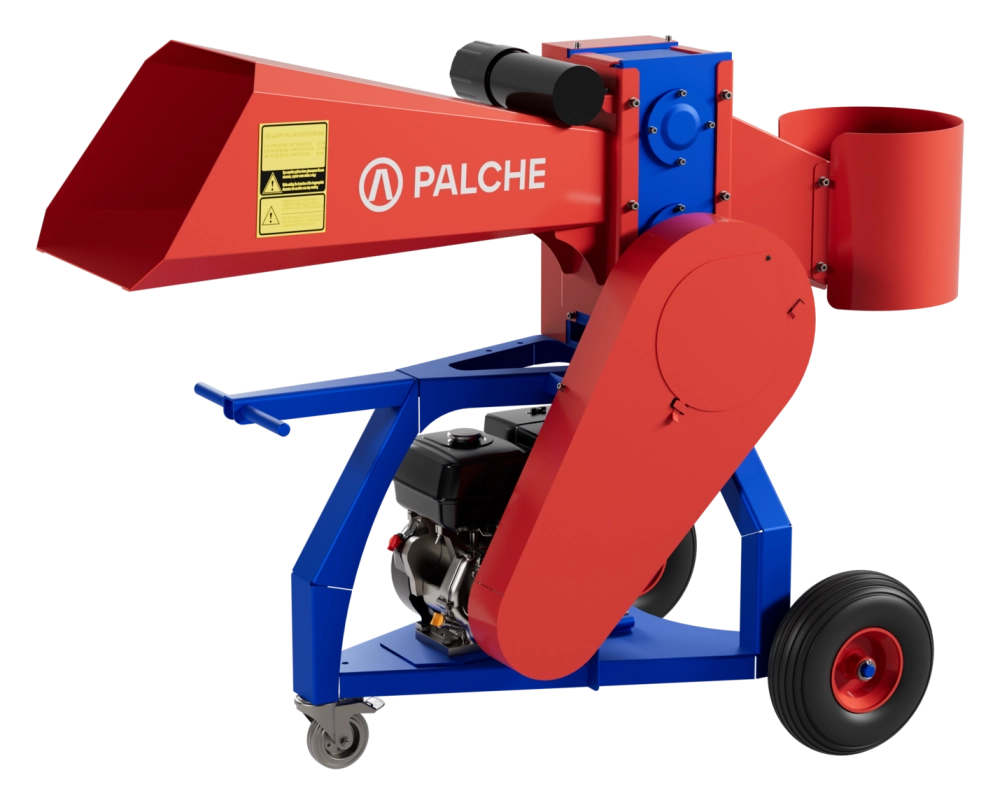

Branch Shredders

Branch shredders manufactured by the PALCHE TM are designed for shredding (by cutting into pieces) wood waste, namely: branches, tree crowns, laths, boards, slabs, and other materials. The branch shredder is capable of cutting branches up to 21 cm in diameter. The resulting wood pieces have a length of 9 to 18 cm, which is ideal fuel for boilers, fireplaces, stoves, and for charcoal production.

PALCHE TM chippers are represented by the PG series.

The use of a branch shredder is most beneficial for:

- Municipal services, city and village councils – especially during the period of sanitary pruning of tree crowns (removal of dry, old, and damaged branches), formative, or rejuvenating tree trimming;

- Wood processing enterprises – furniture production, manufacturing of pellets, pallets, etc.;

- Forestry enterprises – a large number of branches remain after forest thinning, sanitary felling, clearing of forest roads, and clear-cutting;

- Sawmills – shredding waste after production, such as beams, board trimmings, etc.;

- Farming enterprises – which clear field roads of dense thickets and process wood waste into fuel. It is especially useful to have such a chipping unit for farms with fruit orchards or vineyards. Also, farming enterprises that rent land must first prepare it for the agricultural season and clear it of shrubs for further cultivation.

- Private individuals – use shredders to simplify the process of preparing fuel for boilers, stoves, and fireplaces.

Types of Drives for PALCHE TM Branch Shredders:

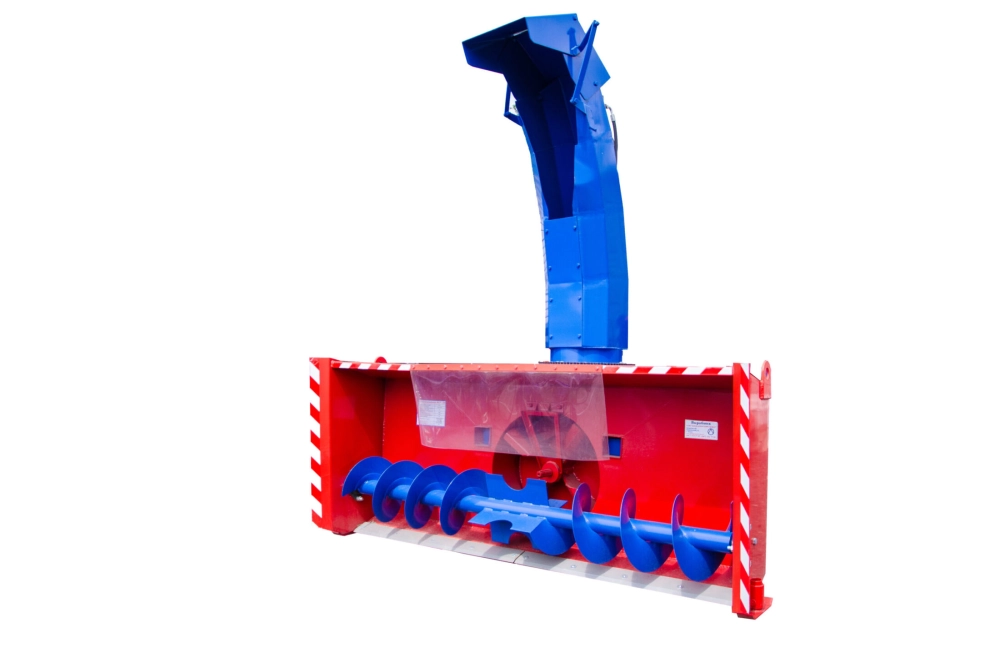

- PTO (Power Take-Off) of a tractor (series "T") – used in mounted shredders connected to tractors via the rear three-point hitch. In this type of drive, engine power is transmitted to the branch cutter through the PTO shaft. The minimum required power for working with the branch shredder is 15 hp (for PG-80T). It ensures the mobility of the device and has increased productivity due to utilizing the tractor's power.

- Electric (series "E") – driven by an electric motor. The final product has a lower cost due to the lower price of electricity compared to other types of drives. Electric branch shredders are equipped with motors of 11 kW and 7.5 kW.

- Gasoline (series "BD") – does not require additional equipment such as a tractor or electricity, which makes it the most mobile option. Fuel consumption is up to 1 L / 10 m³ of finished product. Gasoline branch cutters are equipped with a 16 hp engine.

The branch cutting machines are equipped with a cylindrical cutting system (heat-treated blades).

The mechanism housings are made of certified 20 mm thick sheet metal, with rolled steel shafts on which gear drives are installed. The mechanism automatically draws in the material to be cut. The reliable housing ensures the longevity and stability of the devices. For safe operation, the working elements of the shredders are enclosed.

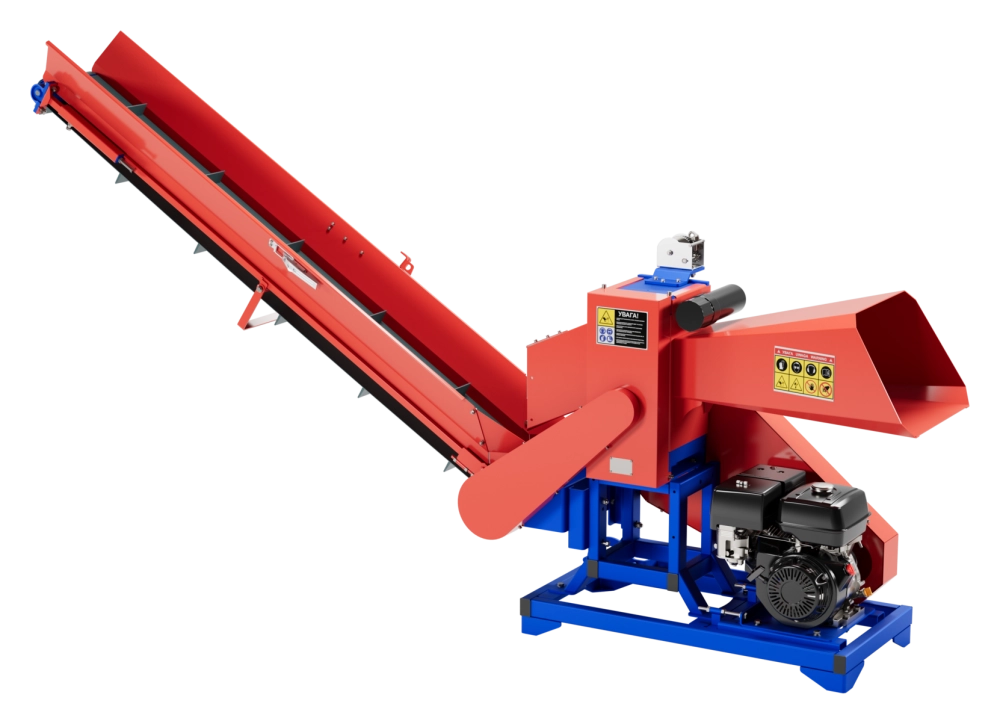

PG series "TK" branch cutters are equipped with a conveyor belt, allowing the finished product to be loaded directly onto a trailer or the bed of a truck.