Who we are

COMPANY HISTORY

- 2002The beginning of operations. A company was created specializing in the distribution of spare parts for Fortschritt brand agricultural machinery. This year marked the beginning of the brand's activities.

- 2008In the village of Palche, Volyn region, our own production of high-quality analogs of spare parts for imported agricultural machinery of brands Fortschritt, Holmer and Ropa was launched. This step became the foundation for creating a full-fledged production infrastructure of the company.

- 2011The company's activities were united under the single brand PALCHE. LLC 'Grandpostach' was created. This structural transformation increased the efficiency of company management.

- 2012The company expanded its activities – serial production of aggregates began. This step allowed to diversify the company's activities.

- 2014LLC 'Grandpostach' organized the production of high-quality analogs of spare parts for world-renowned brands Claas, Lemken and Farmet. These spare parts fully comply with compatibility standards with original equipment and strengthened PALCHE's position in the market for this equipment.

- 2015Years of successful work allowed the company to establish itself not only in the Ukrainian market, but also to enter the European market. A PALCHE trademark representative office was opened in Poland in Lublin. This allowed the company to gain broader access to clients and partners in EU countries.

- 2016Production of high-quality analogs of components for John Deere and Geringhoff brand equipment was mastered, which significantly expanded the product line in these areas and substantially increased the company's competitiveness.

- 2018The company implemented a strategic project to expand the production and warehouse complex, increasing the total infrastructure area by 3,600 m². The complex included modern production, administrative, warehouse and technical facilities, ensuring further production development.

- 2019The company applies the Lean Production concept (lean manufacturing) - a process of implementing a management concept that involves a relentless pursuit of eliminating all types of waste in business processes to achieve maximum value for the customer.

- 2024PALCHE's range includes over 1,000 high-quality spare parts for equipment from seven world brands: Claas, John Deere, Geringhoff, Holmer, Ropa, Lemken and Farmet. Such a wide range confirms the company's ability to meet the needs of the modern agricultural market for high-quality spare parts.

Directions of work

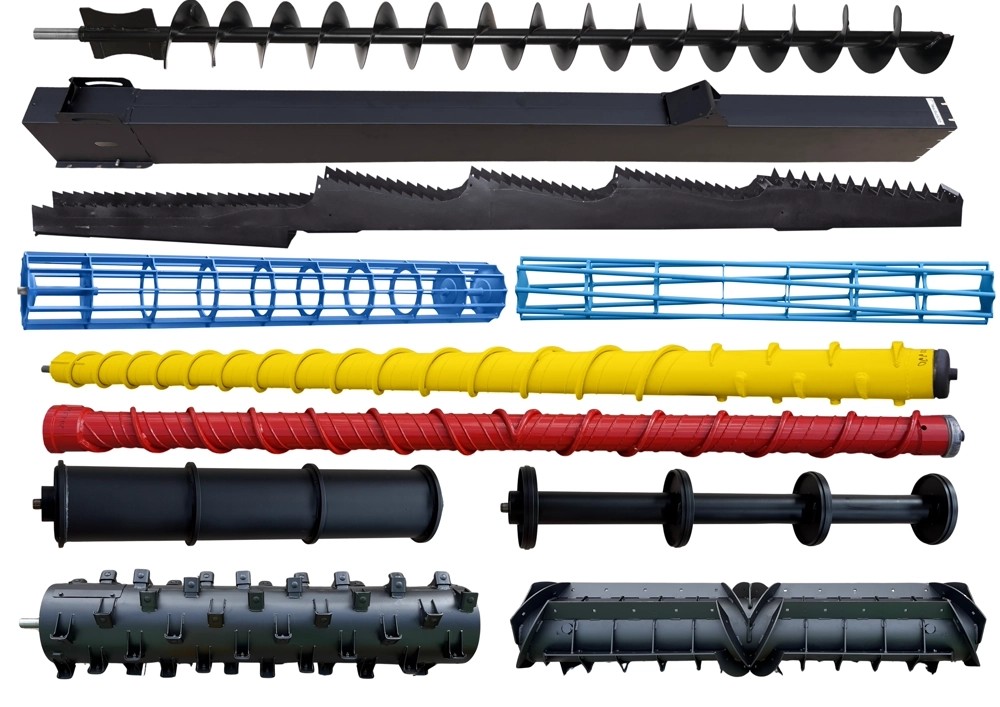

TM PALCHE spare parts

We offer a wide selection of original and high-quality analog spare parts for agricultural machinery from leading world brands: CLAAS — spare parts for grain and fodder harvesting equipment that ensure reliability and long service life of machines; John Deere — components that guarantee uninterrupted operation and high performance of equipment; GERINGHOFF — quality spare parts for harvesting equipment that optimize crop harvesting; HOLMER and ROPA — spare parts for beet harvesting equipment with maximum resource and precision; LEMKEN and FARMET — spare parts for tillage equipment that increase efficiency and durability of equipment. All parts undergo quality control, which guarantees their compatibility and safe operation. By choosing TM PALCHE spare parts, you get a reliable partner with professional support and quality guarantee.

Aggregates

A team of experienced designers and engineers creates innovative and reliable equipment for agricultural and municipal enterprises. We offer a wide selection of modern equipment, including wood chippers that enjoy well-deserved popularity among consumers.

Our wood chippers are distinguished by high quality, durability and operational efficiency. The range includes models with gasoline and electric engines, as well as units powered by tractors.

About production

Many years of experience in manufacturing high-quality analog spare parts and serial production of aggregates. Since the beginning of analog spare parts production in 2008, we have significantly expanded our capacity and product range. Today PALCHE production is a modern, high-tech complex. We use automated processes and have implemented Lean Production principles. This guarantees stable, uncompromising quality of every manufactured part and high production efficiency. In addition to components, we also use our experience and innovative solutions in the production of aggregates. Our products are developed taking into account many years of experience. These products are oriented towards the needs of agricultural holdings, farmers and municipal enterprises. All aggregates come with an official 3-year warranty, which emphasizes our confidence in the quality of our final products.

We work for your benefit

At PALCHE company, we believe that high-quality and reliable spare parts are the guarantee of productive and successful operation of your combine harvester. That is why we direct all our efforts to forming a range of parts that meet the highest standards of quality and reliability, ensuring long-term service life of your agricultural machinery.

Our values

- Honesty

- Professionalism

- Mutual Respect

- Efficiency

- Responsibility

- Innovation

- Discipline

- Partners

- Quality

- Teamwork

Our strategy

- Continuous development

- Outstanding achievements

- Long-term stability

Our advantages