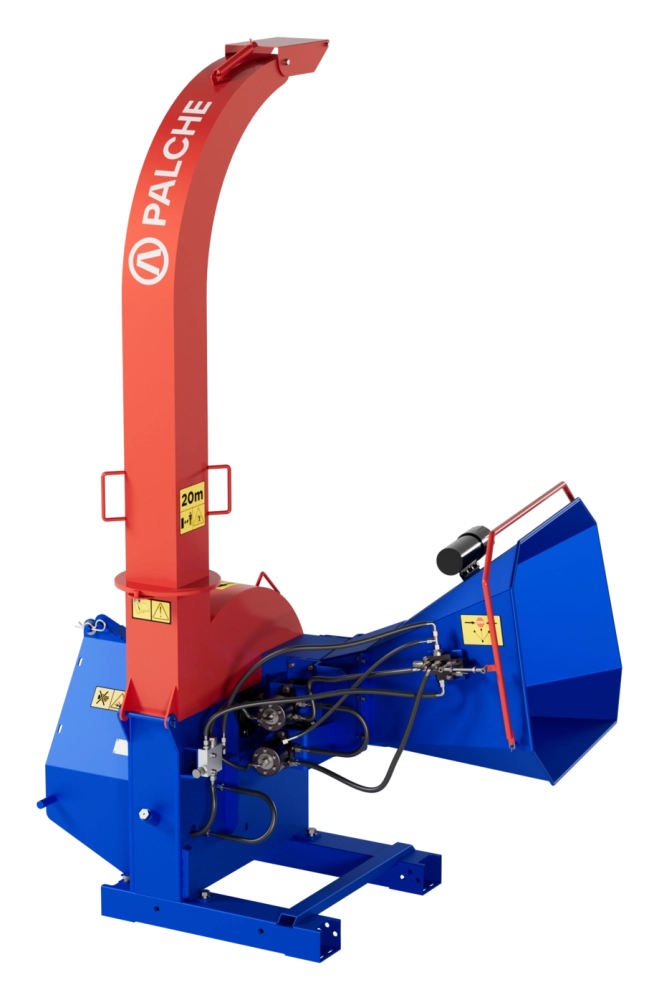

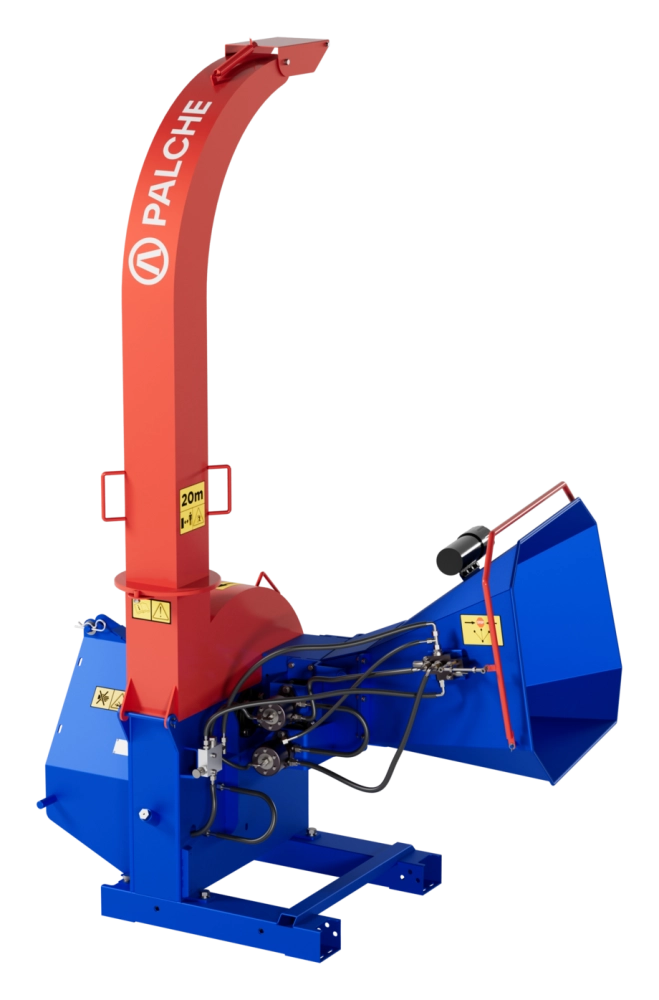

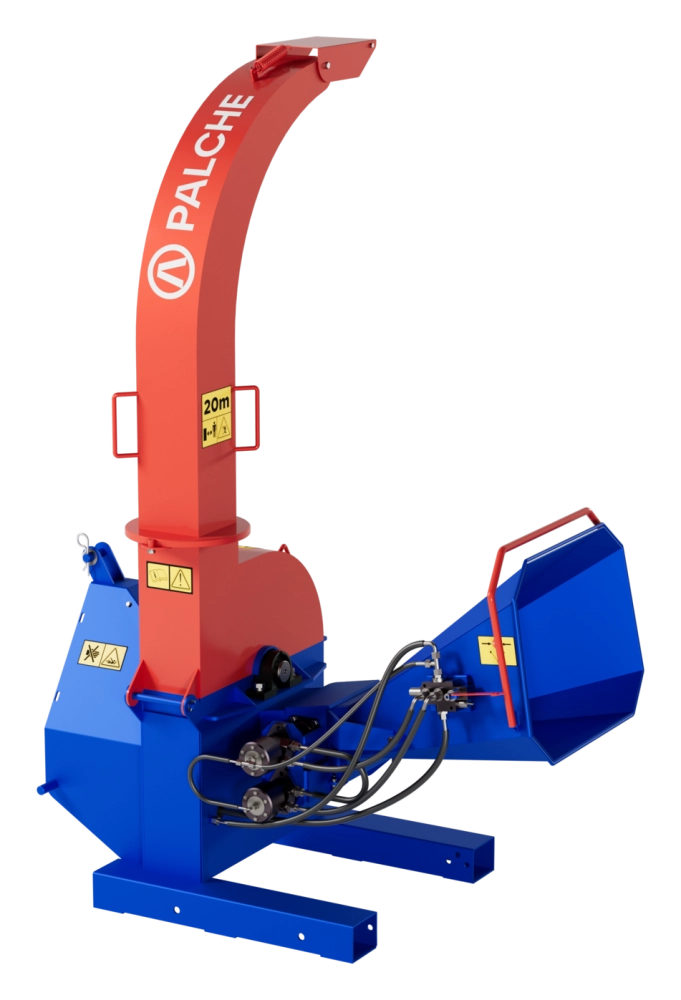

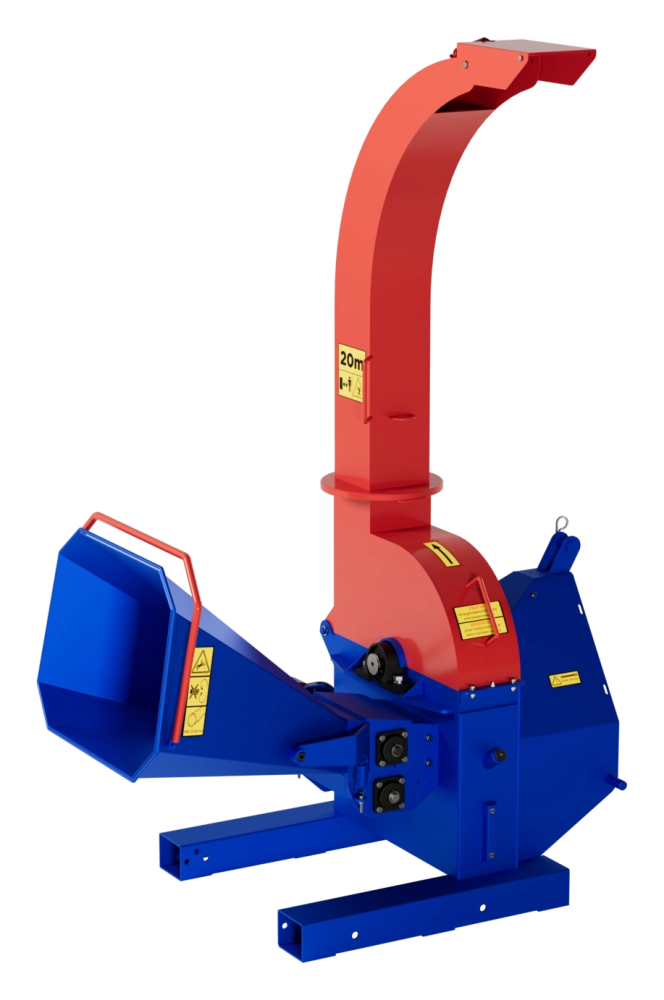

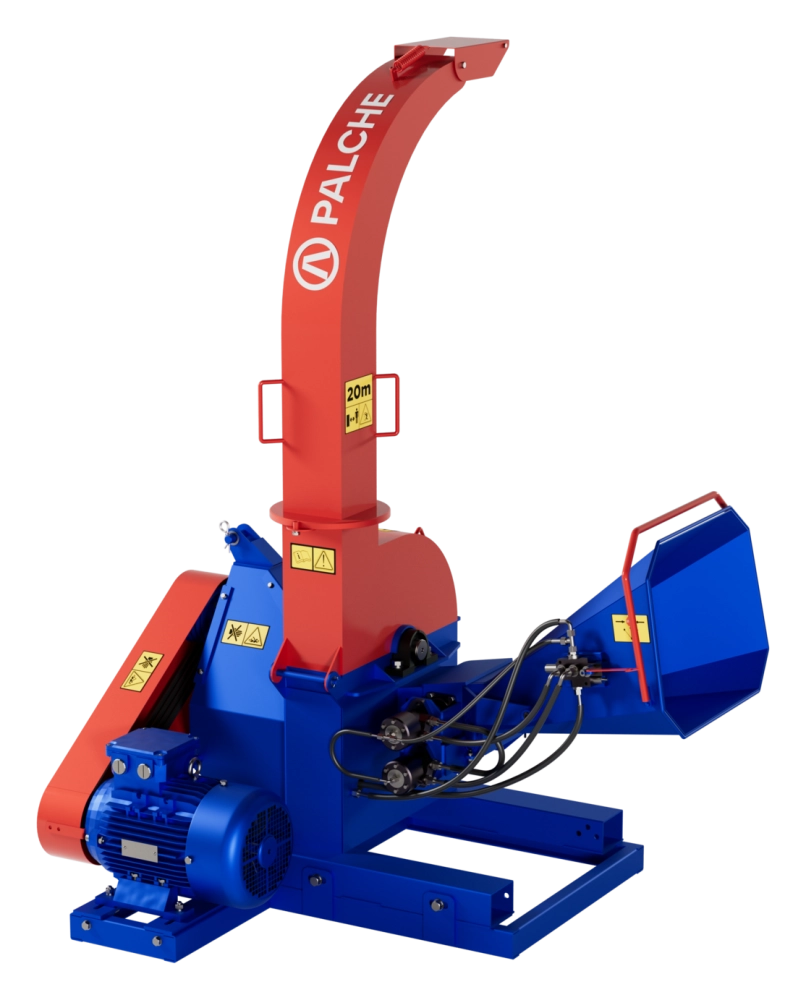

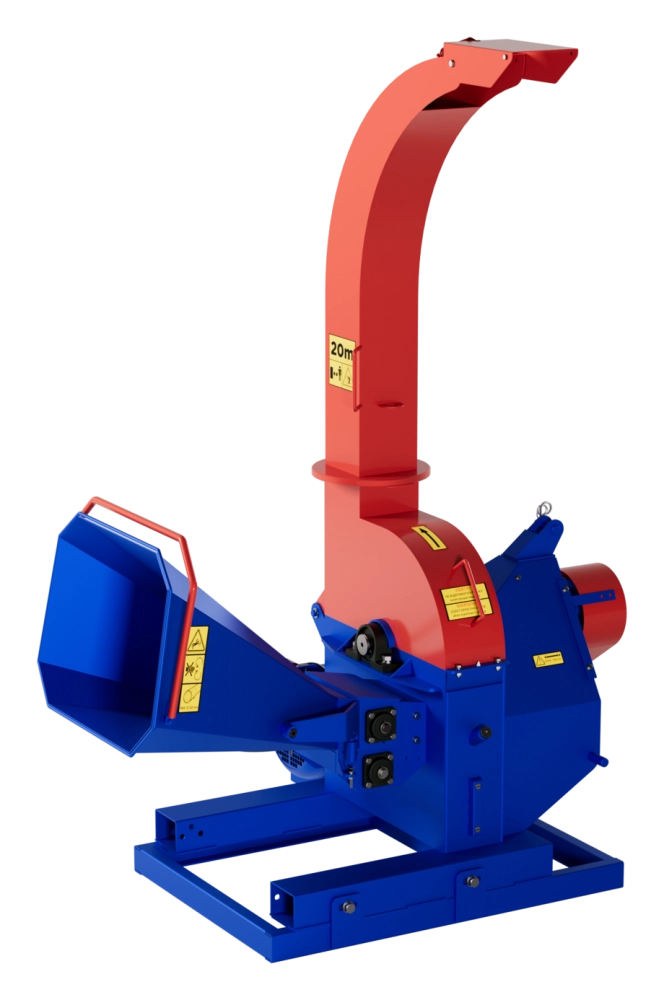

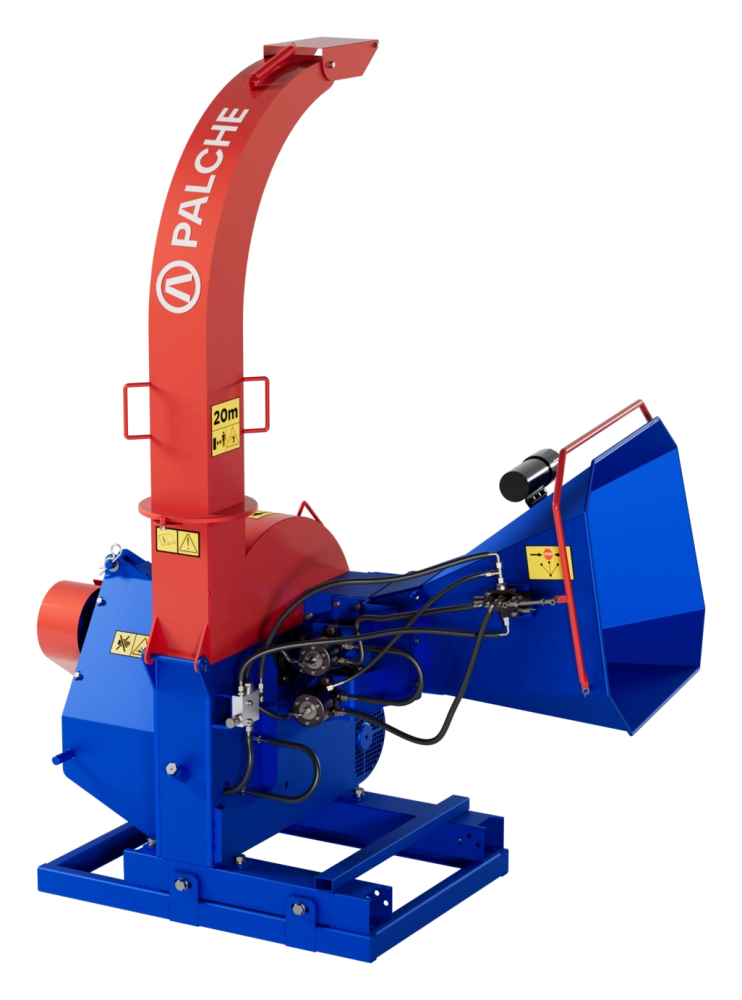

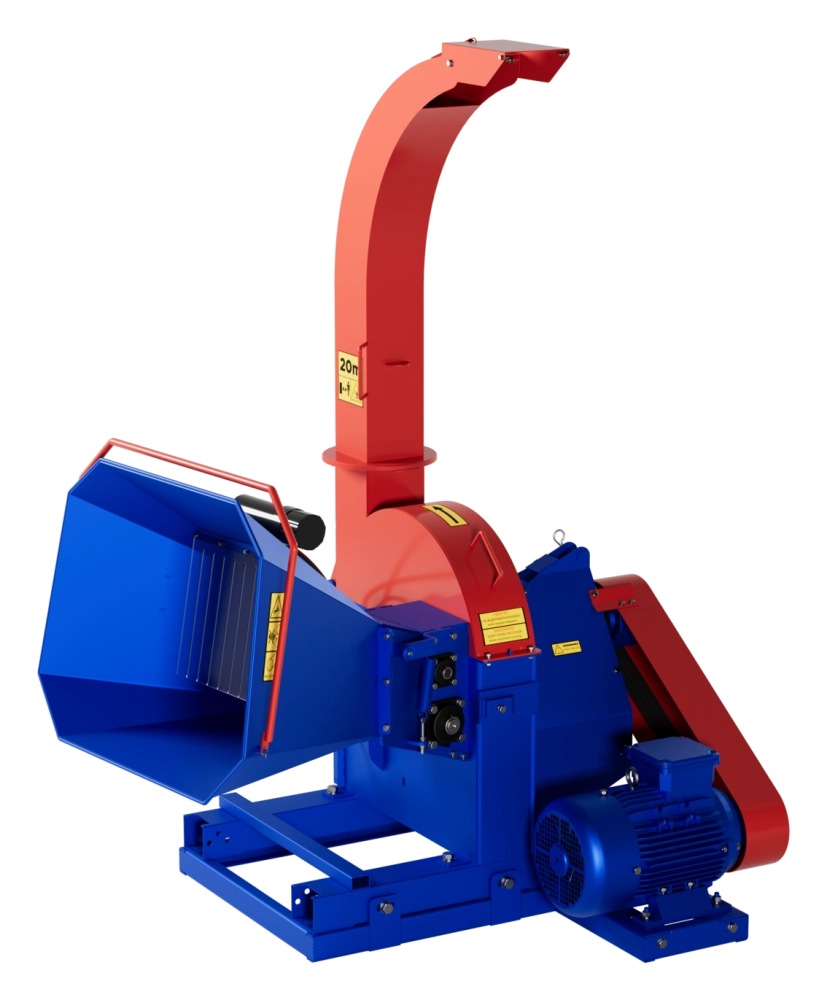

Wood Shredder (Chipper) manufactured by TM PALCHE

The wood shredder (chipper) manufactured by TM PALCHE is characterized by its ability to process fine wood waste, logging residues, laths, slabs, and sawmill waste into fuel chips, which are especially convenient for use as fuel in screw-fed boilers. Through additional processing, technological chips are produced, from which pellets and fuel granules are made.

The chipper is used at logging enterprises, sawmills, various woodworking companies, pulp and paper mills, and municipal services.

PALCHE TM chippers are represented by the PL series.

The size of the wood that the PALCHE TM shredder is capable of processing into chips is up to 160 mm, depending on the model. The output fraction size ranges from 5 to 30 mm and is adjusted by regulating the knives on the cutting disc. The productivity of the shredder models ranges from 6 to 9 cubic meters of chips per hour.

The PL series of chippers from TM PALCHE are available with the following drives:

- PTO (Power Take-Off) (series "T") – wood shredder for a tractor;

- Electric drives (series "E") with a power of 30 kW.

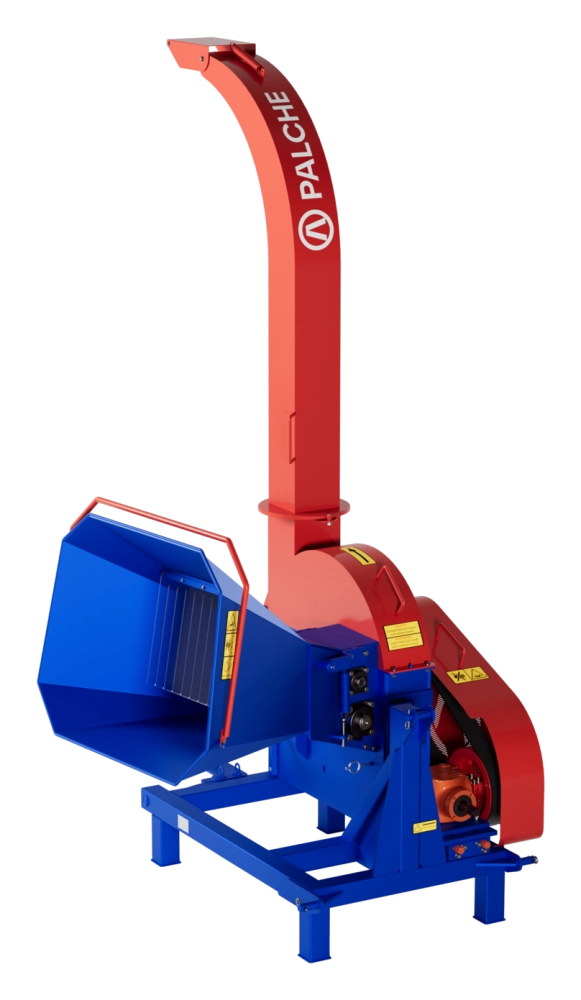

A unique feature of the electrically driven chippers (Pl-E series) is the removable frame with the electric motor installed on it. This transformation allows the wood crusher to be attached to a tractor and use its PTO (Power Take-Off shaft), making it universal and mobile.

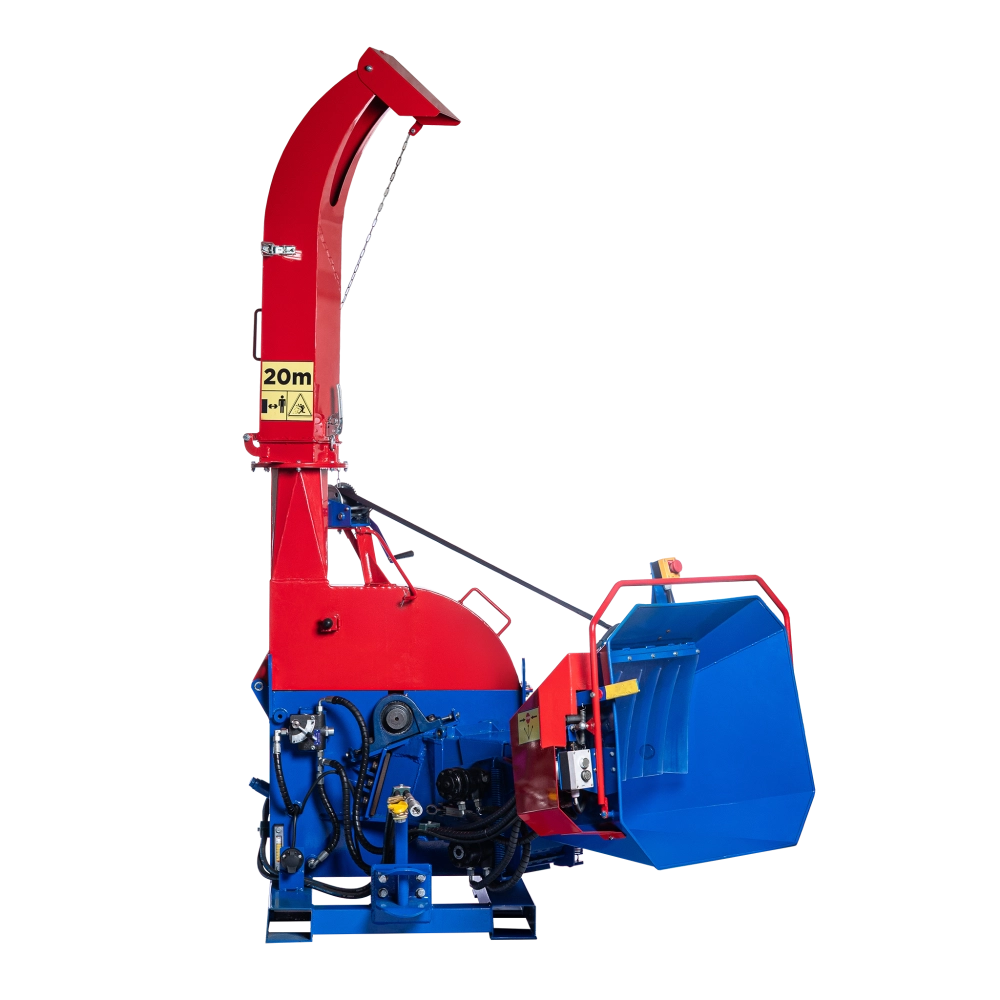

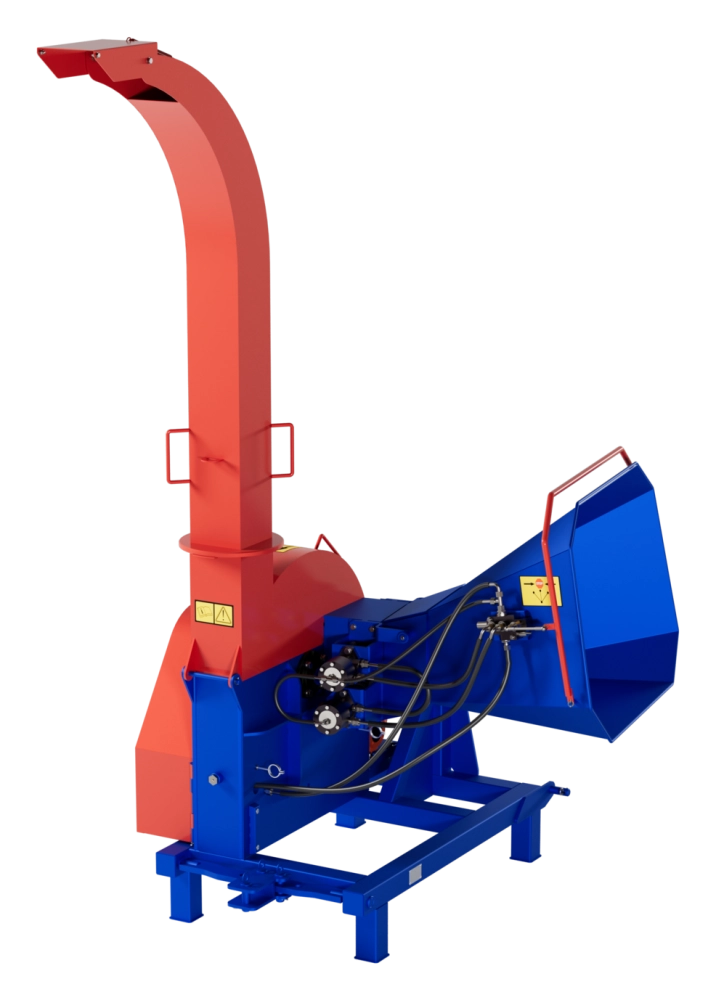

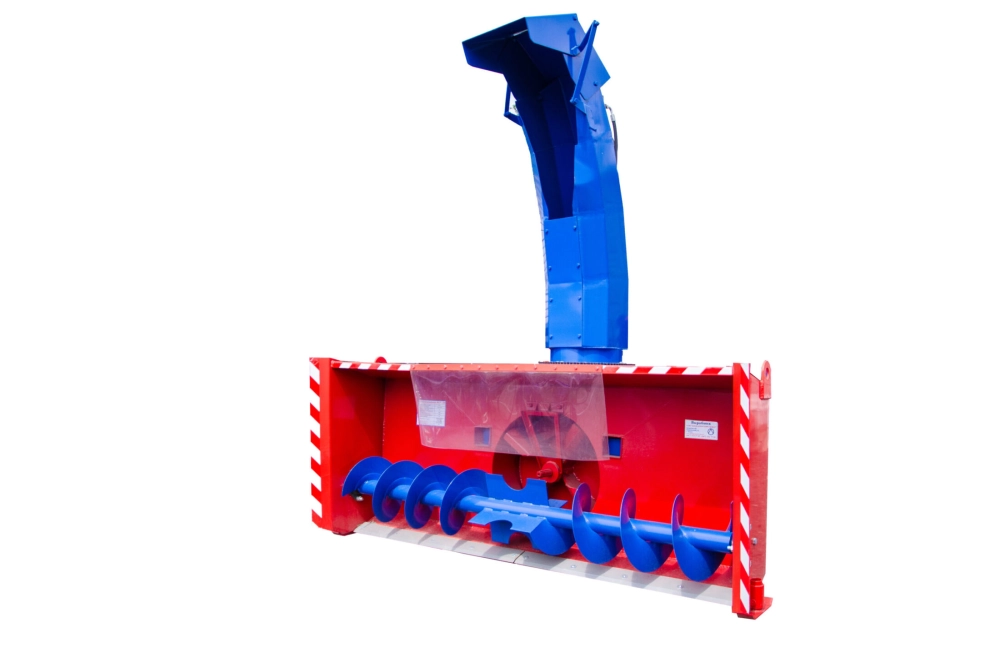

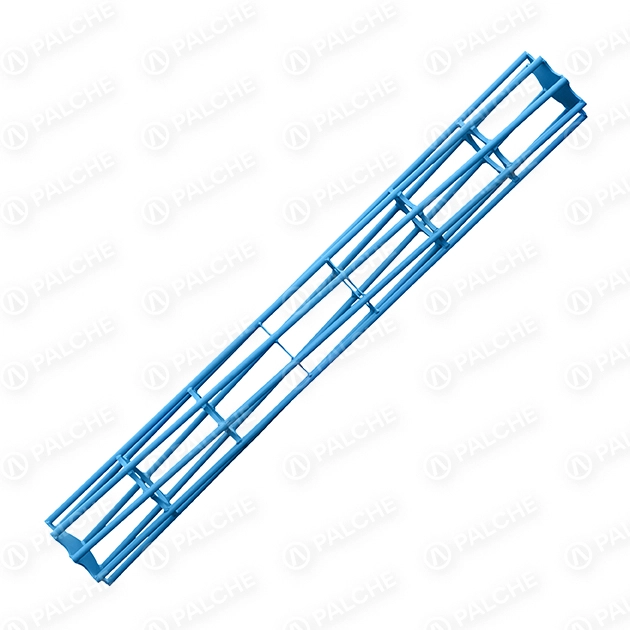

The wood shredding machines consist of a welded body, which forms the basis of the structure, a frame on which the electric motor and other parts are attached, and a casing that protects the mechanisms. Inside the casing is a shaft with a disc, mounted on housing bearings.

The raw material is drawn in by drums powered by two hydraulic motors and fed to the cutting disc, which is 4 centimeters thick. The hydraulic system is driven by the PTO shaft or the electric motor, depending on the shredder model.

Wood waste is fed into the shredder through a loading hopper with a protective curtain for the operator.

The chips are ejected through the chute by the disc blades and the air flow, and the direction of the ejected shredded wood can be adjusted using a deflector. The chute is adjustable by 360 degrees, and the chip ejection height is up to 4 meters, allowing the material to be chipped directly into a trailer. Replacing or adjusting the knives of the cutting disc (for example, to set the fraction size) is easily done by lifting the top cover.